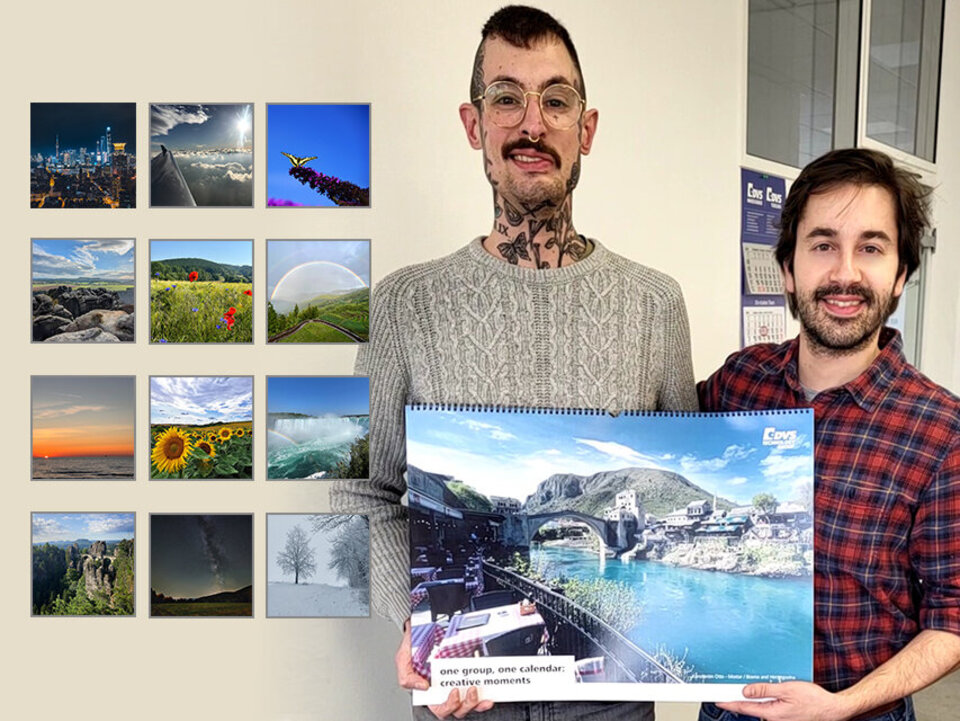

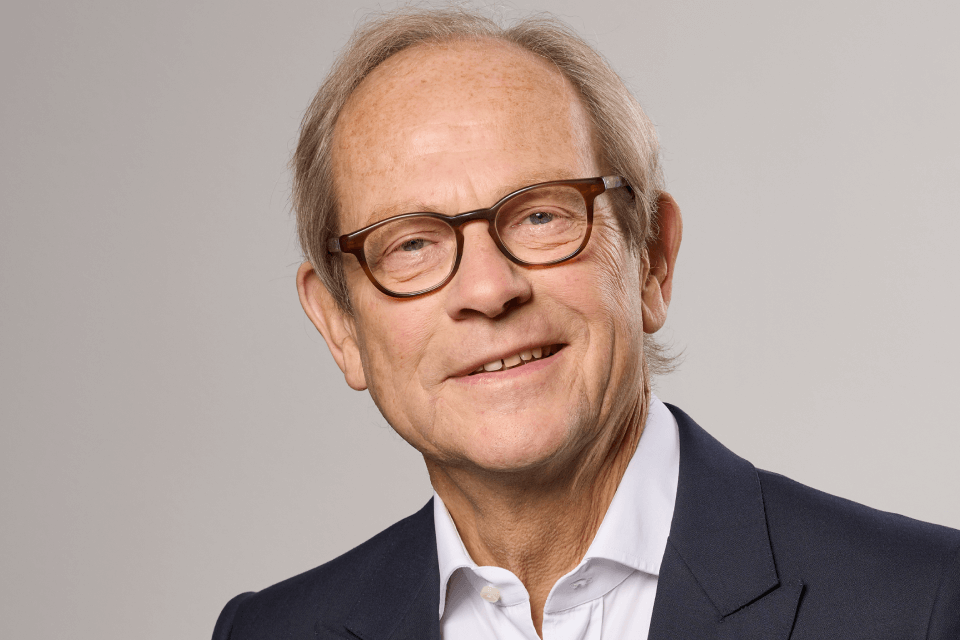

From Apprentice to Technology Developer – Driven by Curiosity, Courage, and Passion

At just 14, Vladimir Karic already knew where his path would lead: to the DVS Group. After finishing high school, he took the bold step of moving to a new city and starting his career as an apprentice.

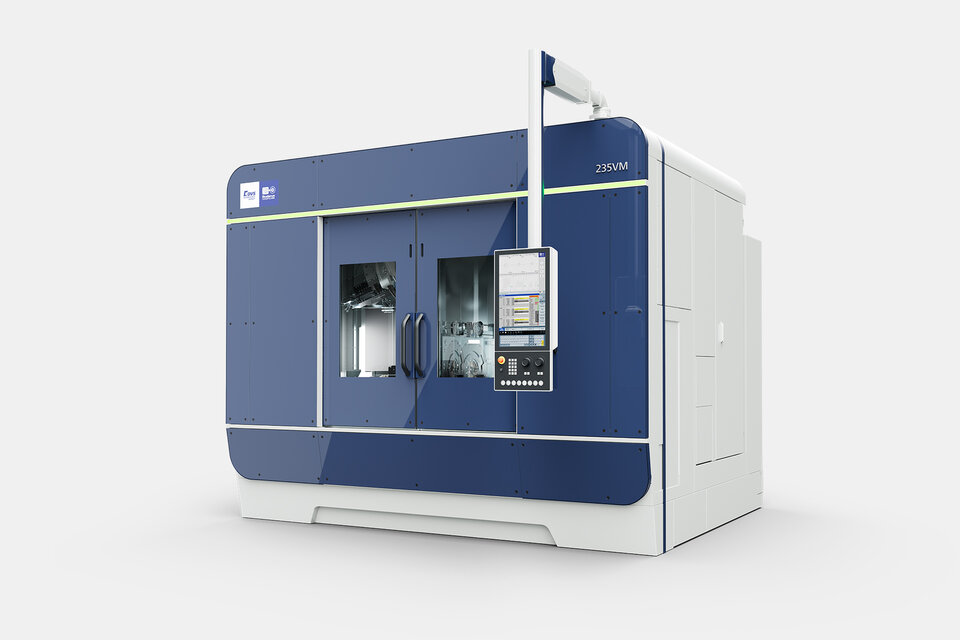

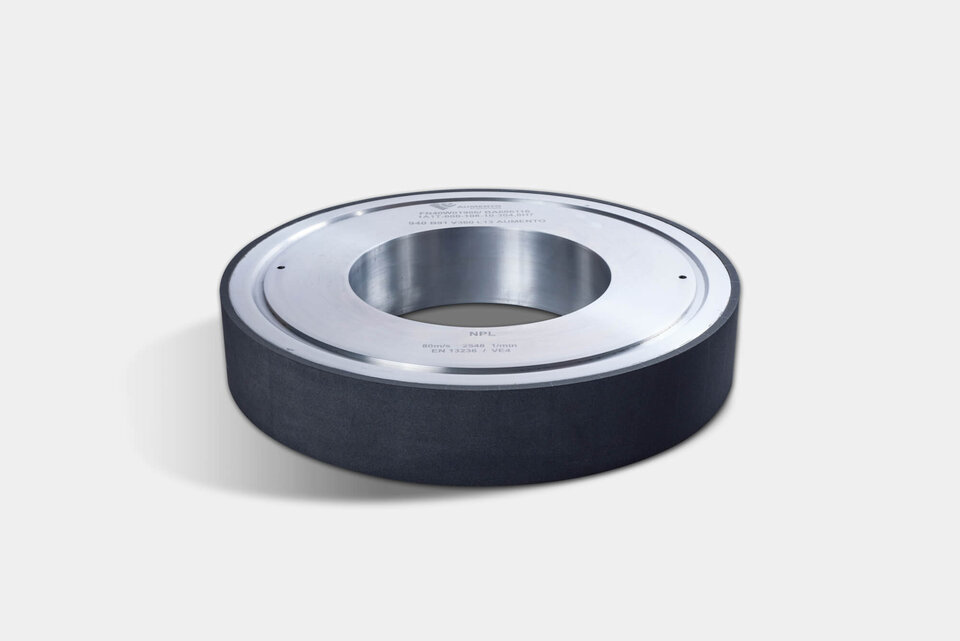

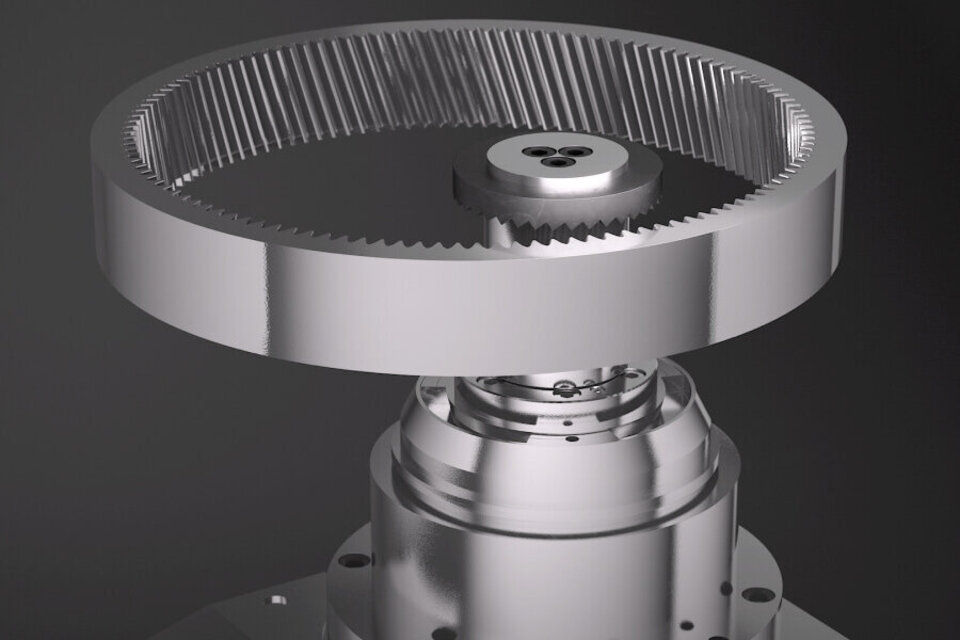

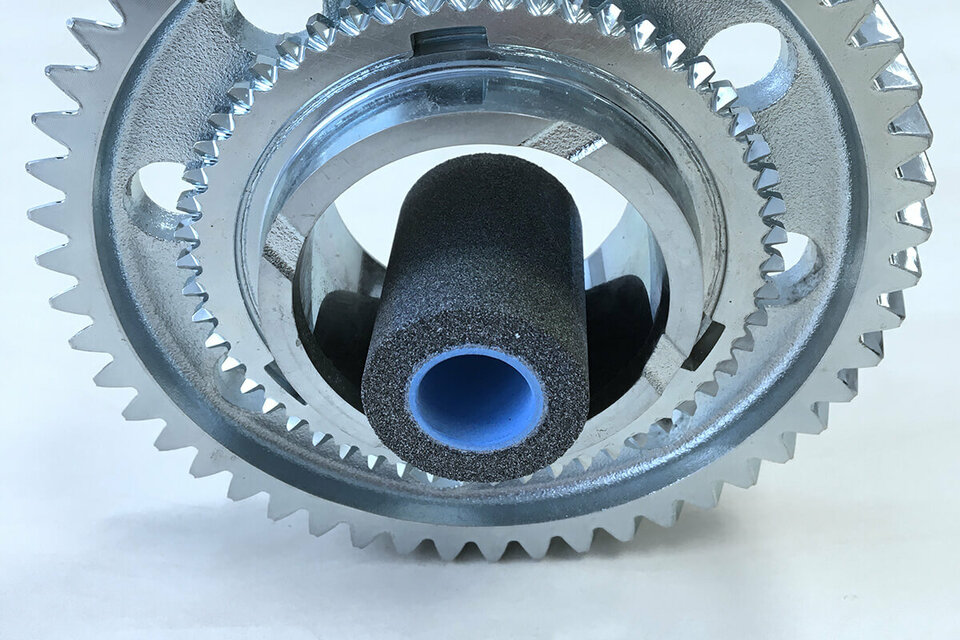

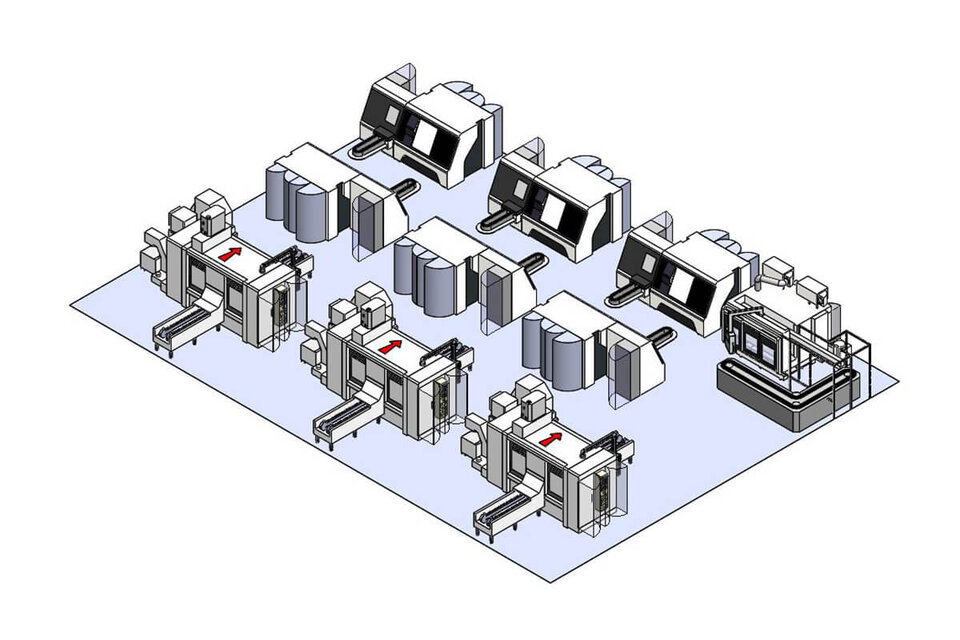

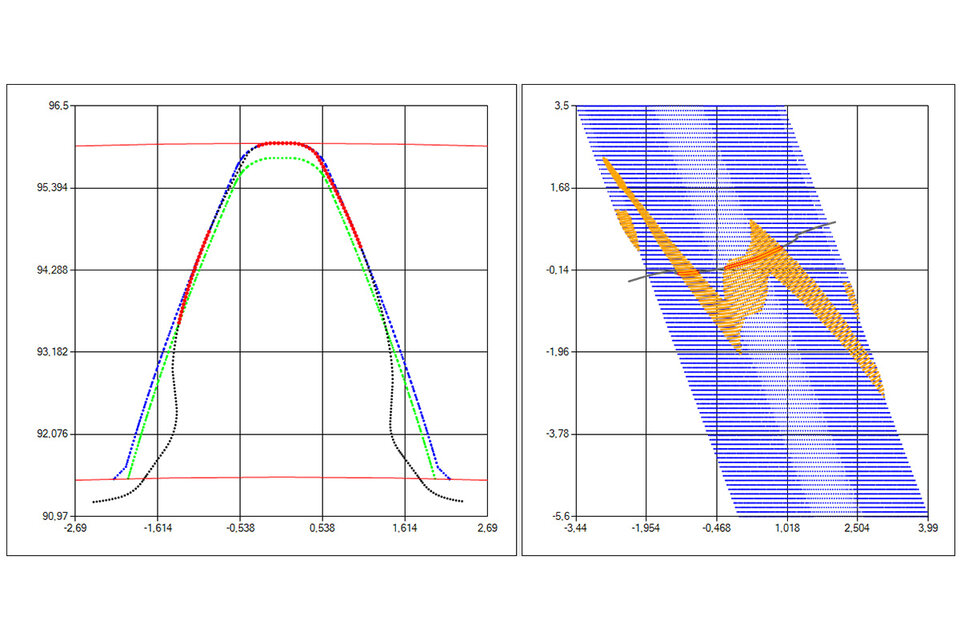

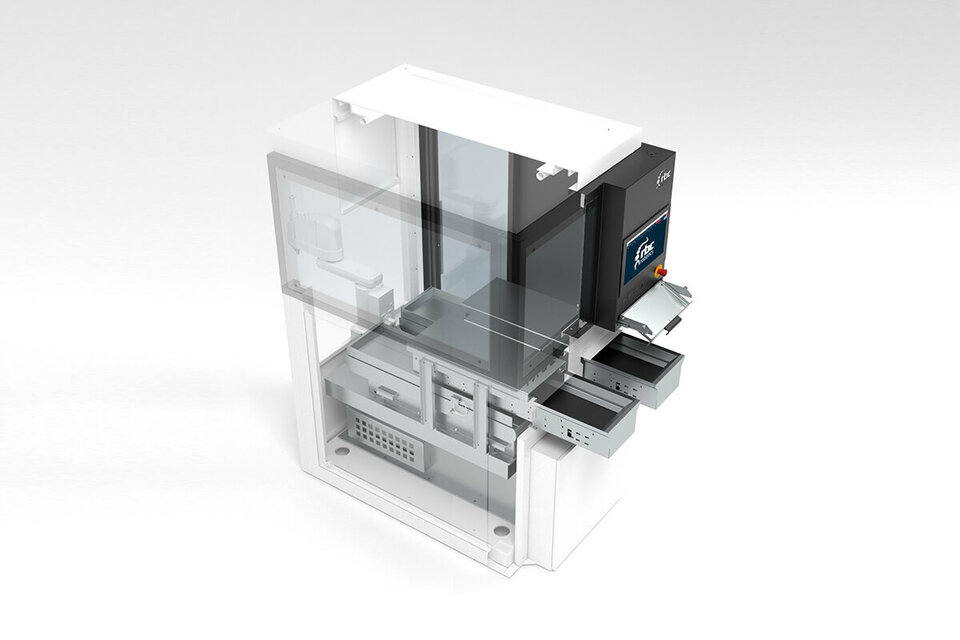

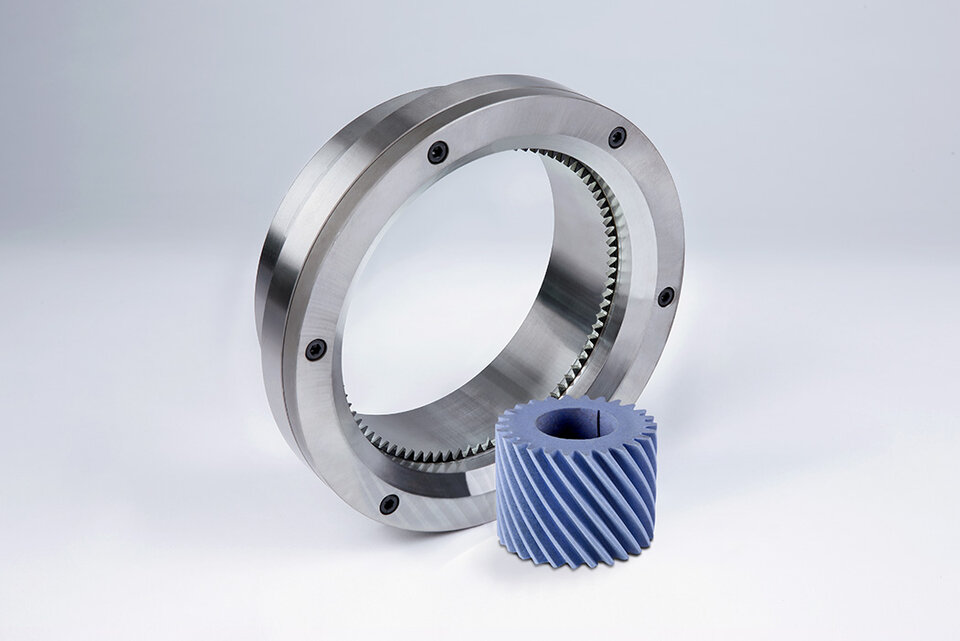

Today, more than ten years later, he works as a technology developer on high-precision grinding processes, including applications for coated brake discs in the context of the upcoming EURO 7 standard. His journey has taken him from global machine setup assignments through the development department to holistic process and machine development.

What drives him? Curiosity. The determination to question things – and the ambition to actively advance technology.

His message to the next generation: Don’t wait for opportunities – seize them. Stay committed, even when things get difficult. It is precisely the challenging paths that provide the most valuable experiences.