"Every chain is as strong as the weakest of its links," as the saying goes. In terms of machine tools and tools, this can be confirmed: Only when all components are perfectly coordinated, premium quality can be achieved overall. For this reason, the specialist companies of the DVS Group concentrate on their respective expertise on the one hand, but on the other hand also make targeted use of the group's internal synergies in order to achieve more in the interaction of the individual components than the sum of the individual components could.

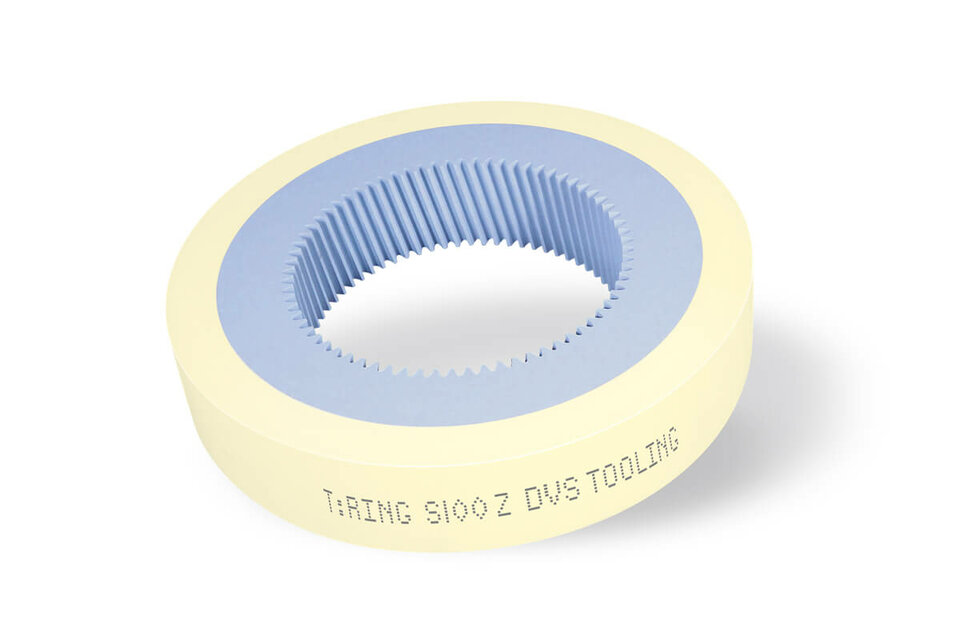

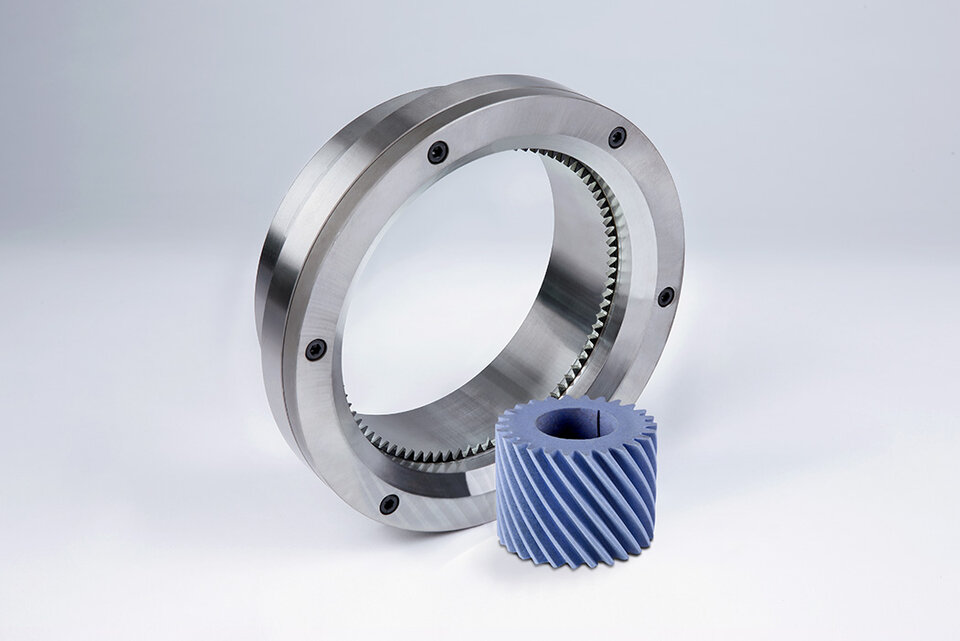

The Buderus iCompact is a perfect example of this. To enable the experts at Buderus to concentrate fully on the further development of this innovative, modular machine platform, experts from DVS Tooling and Naxos Diskus are dedicated to the highly complex and elaborate development of premium quality diamond dressing tools. For two years already, an interdisciplinary team created the basic development for this. Since November 2020, DVS Tooling has been responsible for everything from design and production to application engineering of the dressing tools. This ensures short decision-making paths, rapid development and enables concentration on core competencies while maintaining an ongoing exchange of information.

Customers benefit from components that are optimally matched to each other - this means higher workpiece quality, higher throughput, improved cost-effectiveness and service support that has both the machine and the tool know-how.

So the calculation "1+1=2+n" works out above all for the customer: orchestrated expertise simply accomplishes more.