Gears for the robot industry

The worldwide trend towards automation and digitalisation in manufacturing is ensuring sustained growth in the robot industry: according to the Federal Statistical Office in Germany, one in two major industrial companies already uses robots today.

The future of automation lies above all in the intelligent combination of the respective strengths of man and machine. In order to achieve better results, conventional procedures and processes are being rethought from the ground up. In industrial production, this is primarily a matter of improved ergonomics with a simultaneous reduction in manual processes. As a result of this development, robotics has grown by an average of more than 10% in recent years. An end to this growth is not in sight for the time being - robots are a key component in the automation of production processes.

Special challenges for drive technology

Robots place extreme demands on positioning accuracy with high dynamics. For this reason, low backlash gears with high torsional stiffness are used in the development of drives for jointed-arm robots. However, this requires a correspondingly high-quality production technology for these gears. Robot gearboxes have a high transmission ratio and a compact design. Planetary, shaft and cycloidal gearboxes are used as robot gearboxes, as well as new gearbox solutions such as the Galaxie® from Wittenstein. Cycloidal gearboxes currently account for the largest market share in Asia. The high transmission accuracy requires a limitation of tolerances, so that the gear profiles, the pitch accuracy and the position accuracy must meet increased requirements. Even small deviations in the tooth width or minor positional deviations lead to variations in the rigidity of the drive. Due to the unfavourable size ratios, the robot's compliance at the tool tip is many times greater than the play in the gear.

In cycloidal gears, the challenge is to machine the gear teeth in relation to the cam bores. Here, tight tolerances must be maintained in order to achieve a minimum backlash. On conventional gear cutting machines, the gears are machined independently of the cam bores. Here the position orientation must be ensured by the clamping device.

Is it possible to reduce costs and increase quality at the same time?

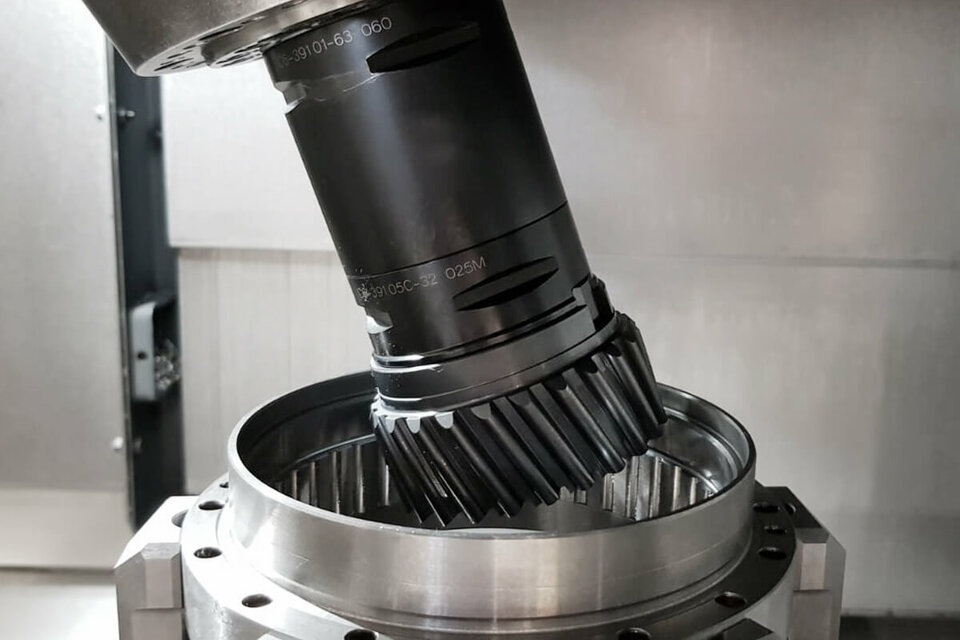

The machining strategy, which is realised on a PITTLER SkiveLine, follows a different approach. By machining the toothing and the cam bore in one clamping, the clamping device for machining a cycloid disc can be designed more simply without negatively influencing the form and position quality. The advantage of complete machining in one clamping is that the reference of the cam bore and gear teeth can be generated and corrected via the machine. This machining strategy even leads to a further improvement of the position quality. In this way, the PITTLER SkiveLine contributes to solving an apparent conflict of objectives - to reduce manufacturing costs with improved quality.

In addition to external gearings, internally toothed housings can also be completely machined on a PITTLER SkiveLine. This is possible by creating the special profiles with PITTLER Skiving and machining all other functional surfaces by turning, drilling and milling. The machining of components for robot gears on a PITTLER SkiveLine is not limited to the green machining itself. To achieve the highest quality, the already toothed and hardened components can be finely machined on the PITTLER SkiveLine. Here PITTLER can fall back on the modular technology of the DVS Group.

The PITTLER SkiveLine thus proves once again that no special machines are required for the manufacture of high-precision gearings, but that the key to success lies in the flexible and scalable basis of the DVS modular technology system. For this purpose, machining centre, clamping and tool technology must be coordinated.