In certain areas of application, modern 3D printing offers enormous advantages - Werkzeugmaschinenbau Ziegenhain GmbH makes targeted use of this development.

Already in March 2018, the first MakerBot Replicator+ 3D printer was introduced at the WMZ in Ziegenhain, North Hesse. In combination with MakerBots material Tough-PLA, developed for high demands, the technology has since then primarily supported new developments and test parts.

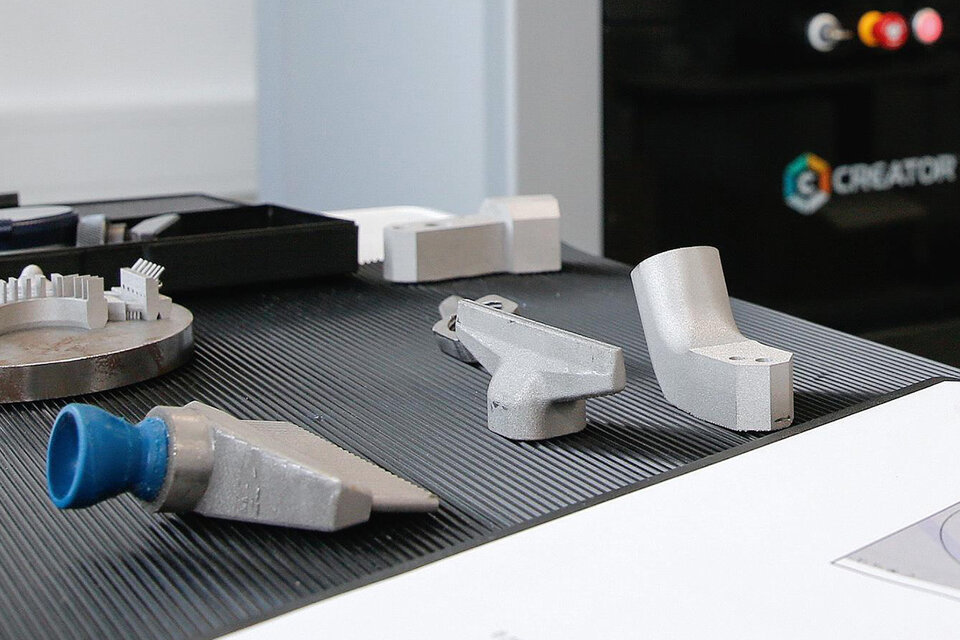

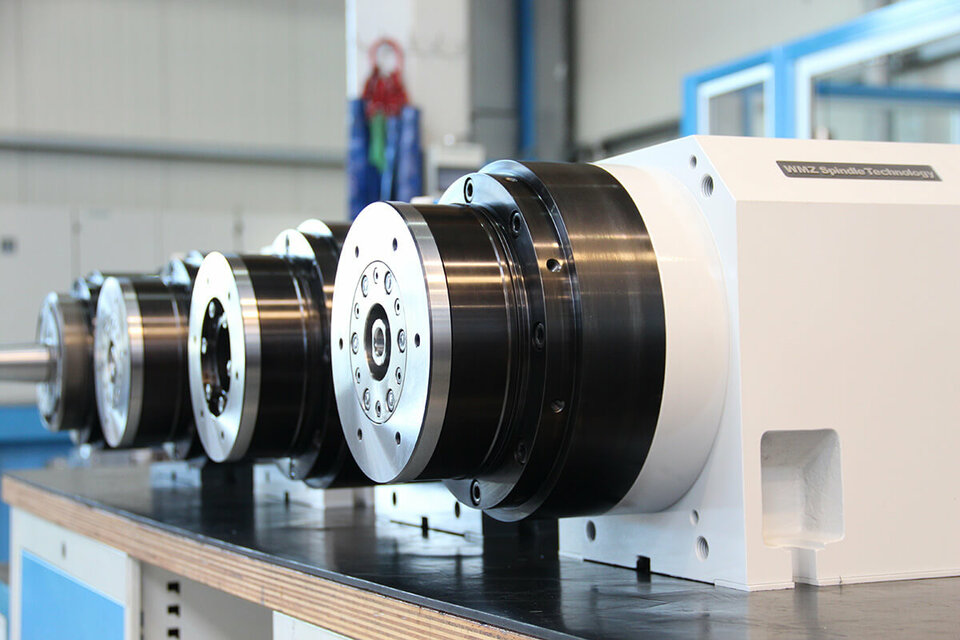

The main application area of the industrial 3D printer is certainly the creation of complex models for sales and development. Machine bed models, hobbing units and construction models are produced quickly and inexpensively from the resistant printing material at the WMZ, and new applications are found almost daily.

In addition to the use for construction and machine models, the WMZ also uses 3D printed Tough-PLA parts in work preparation. Furthermore, they are also used as protective covers for sensors, gripper jaws for loading and unloading a surface grinding machine, centering bolts to protect surface-ground surfaces; spacer rings for shaft seals, sliding guides. By using the MakerBot Replicator+ 3D printer, design changes to required parts can be implemented much faster and cost savings of up to 68% can be realized compared to conventionally manufactured bent and welded parts for the same purposes.