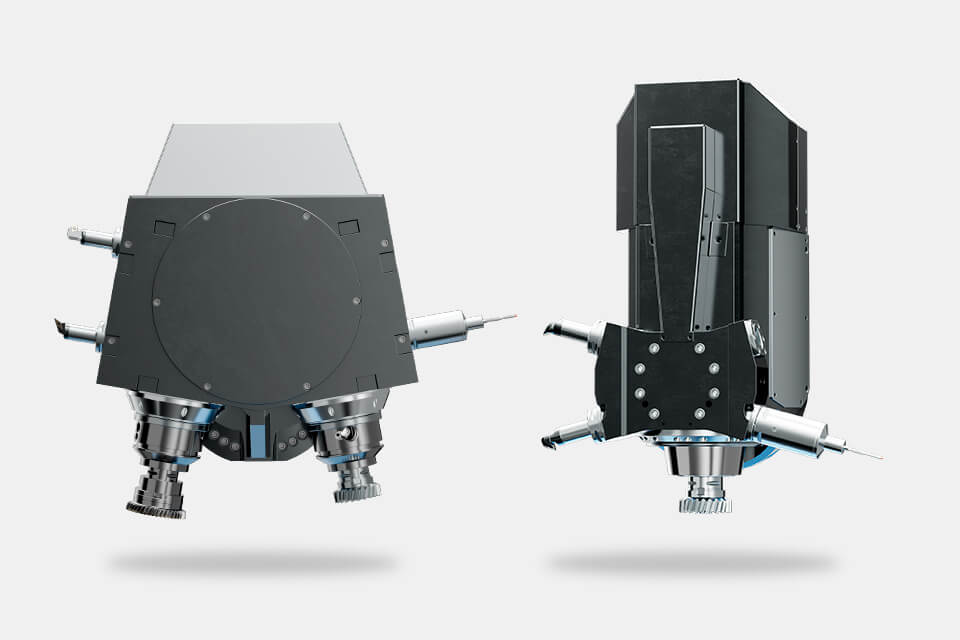

pSkive: MONO and DUO head in comparison

The pSkive from Pittler T&S, presented for the first time at EMO 2023, was specially developed and built with PITTLER SKIVING Technology. The pSkive can not only produce internal and external gears of exceptional quality in a highly productive manner, thanks to its extremely compact and ergonomic design, it can be loaded and transported in a single shipping container. The PV315 version of the pSkive offers impressive flexibility from module 0.3 to module 5 and can machine workpieces with a diameter of up to Ø 315 mm. The PITTLER SKIVING Technology enables the production of internal and external gears with maximum accuracy and quality, making the pSkive the ideal solution for companies that want to produce high-quality gearing parts in medium and large quantities. The machine is available in both mono and DUO head versions. Both variants are presented in detail in this article.

pSkive with MONO head

With a single driven workpiece spindle and up to four fixed holders for turning tools and/or an in-process probe, the standard version of the pSkive enables efficient and precise machining of toothed workpieces.

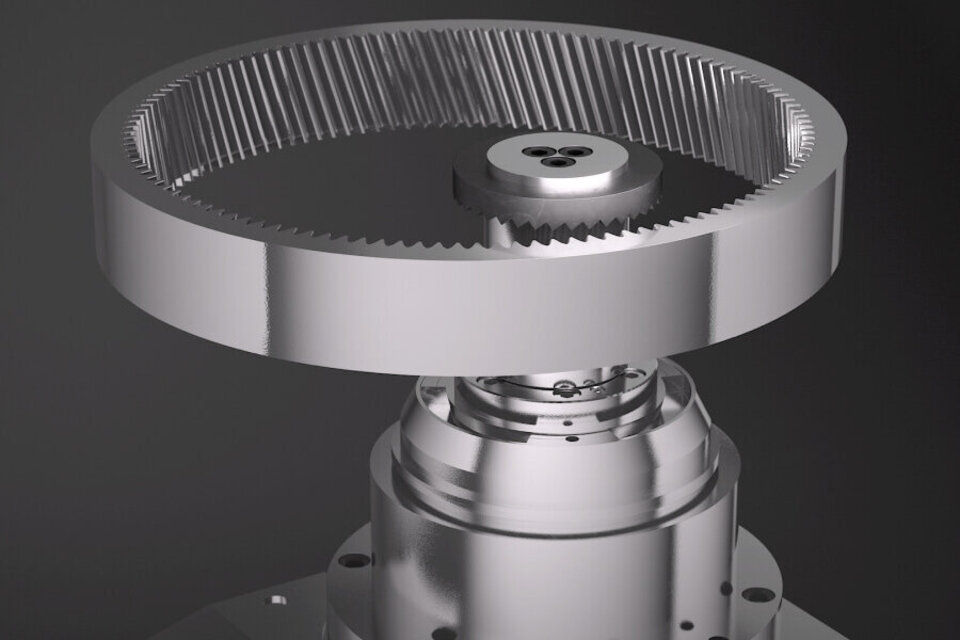

The MONO head with its "turret technology" (infinitely variable swivel range of the head +/-105 °) has the advantage that workpieces can be fully skived, deburred and any reference diameters and surfaces turned in a single clamping operation. This means that not only highly demanding gear cutting qualities can be produced, but also an overall component quality with regard to form and position tolerances.

The MONO head enables the use of an in-process probe, which makes it possible to measure the workpieces during the machining process. This ensures that requirements such as the spherical dimension and flank line of the gearing are met efficiently. The measuring probe also has a positive effect on the set-up process after a tool change. The user interface developed by Pittler supports the monitoring of component quality.

In addition, a sensor for finding the tooth gap for hard skiving can also be implemented, which enables precise and fully automatic control of the process when machining hardened workpieces.

The combination of all these equipment options enables efficient machining and high workpiece quality. The familiar smart operation makes the pSkive skiving machine with mono head a versatile solution for rotationally symmetrical components with internal and external gearing.

pSkive with DUO head

With its sophisticated design and versatile functions, the DUO head helps to increase the efficiency and precision of the production process with the same machine dimensions.

A decisive advantage of the DUO head is its two driven workpiece spindles. This allows two skiving wheels to be mounted, which significantly increases productivity. For example, while a roughing tool (larger modules) is used on one spindle, which enables efficient material removal, the finishing skiving wheel can be mounted on the second spindle to reduce component costs and protect the cost-intensive finishing tool.

Another option for two skiving spindles is the use of sister tools or two different skiving wheels, which are required for a stepped planetary gear, for example.

As with the pSkive with MONO head, up to four fixed holders can be mounted on the DUO head. Further machining operations or component inspections using a probe or the detection of tooth gaps using a sensor are possible. This opens up a wide range of possible applications in the manufacture of complex ring gears.

In summary, the DUO head in the pSkive enables more efficient, more precise and more versatile production while maintaining the same machine dimensions. The ability to swivel to a second skiving wheel in seconds, making the process even more flexible and time-saving, makes it the ideal solution for the production of complex hollow gears.

You missed the EMO and would like to learn more about the pSkive from Pittler T&S? On our website you will find more detailed information about the pSkive and the rest of the machine range, and you can also contact us directly if you have more detailed questions.