Future-proof with Smart and Modular Robot Cells

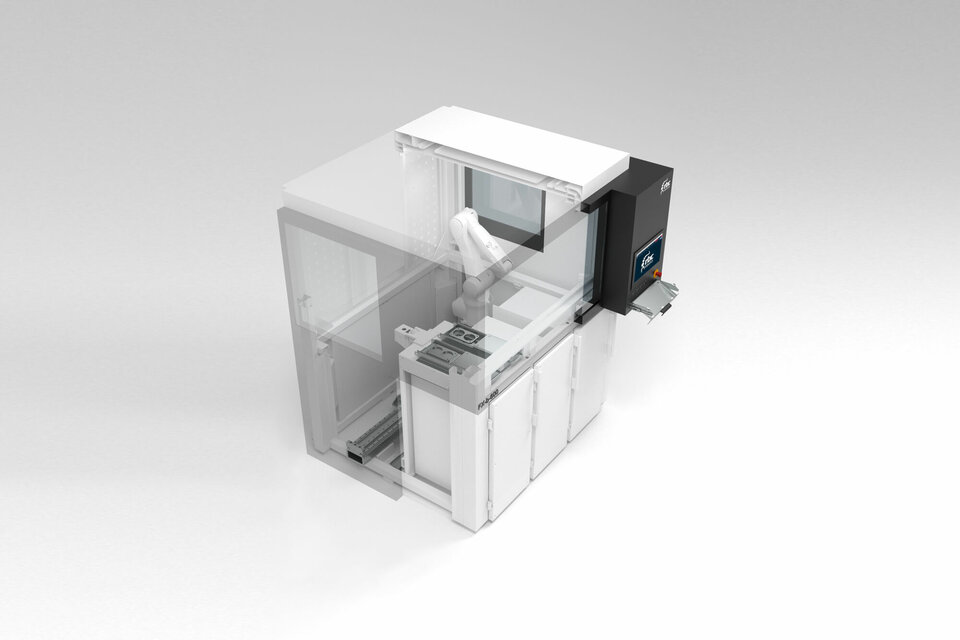

Today, the ability of a company to compete in the future is largely dependent upon its efficiency and flexibility to adapt to shifting challenges – both are key strengths of the smart and modular robot cells from rbc robotics.

Modularity in the DNA

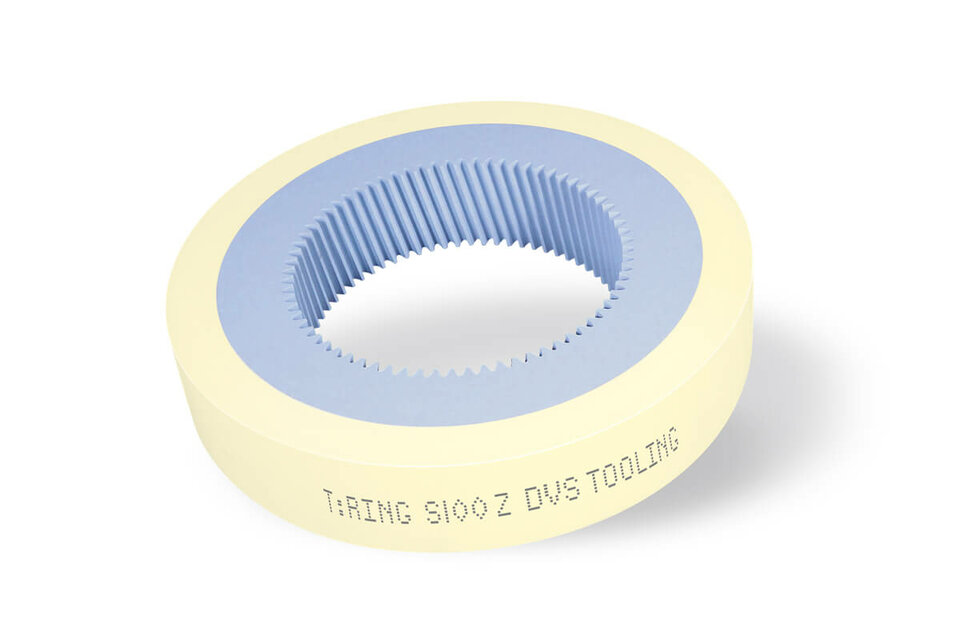

At the DVS Group, modularity is somewhat of a DNA building block. In the production process for electric motor drives, for example, Pittler's skiving, Buderus’s hard turning, and Präwema's gear honing technologies are combined to form an efficient turnkey process for the production of high-end workpieces as needed in today’s modern drives. The modular robot cells from rbc robotics play a special role in this ensemble.

Two decades of experience with a future

Our customers’ requirements are constantly prompting us to push the boundaries of what is possible. Moving this “boundary of possibility” continuously over the course of two decades is what has made rbc robotics a leading solution provider of camera-guided robot systems. Today, the experience gained in well over 500 completed projects is reflected in the modular robot cells of the FX series.

Robot cells create flexibility

Key to future-proof and flexible automation are industrial robots combined with the latest 2D/3D sensors for capturing the position of the components. The modular system enables the seamless combination of individual robotic modules and thus facilitates compact production concepts. A very important aspect of future viability!

Technology toolbox from the DVS Group

The modularity of the robot cells from rbc robotics enables more than just the optimal connection of individual robotic modules: as an automation module, the systems are also an excellent match for the CNC machines from the DVS Group and thus ensure a perfectly coordinated overall production and machining process.

Camera-guided robot systems are very productive

In real production environments, the robot parameters change constantly due to the different sizes, geometries, manufacturing tolerances, and surface characteristics. Thanks to tried-and-tested image recognition solutions, the automation cells from rbc robotics can conquer the next frontier: they are able to see and grip workpieces more precisely and efficiently than ever before.

Smart robot systems for production continuity

Today, almost all industries are affected at all levels by labor shortages, from highly specialized professionals to helpers for simple tasks. And for demographic reasons alone, that will not change any time soon. One of the solutions to this problem is smart, flexible, and camera-controlled robot systems that require minimal space and are very powerful. They are also easy and intuitive to operate and adapt to different components with a high degree of flexibility.

So modular, smart automation solutions create continuity, efficiency, and flexibility in production, which means security in the future. And last but not least, modularity ensures that any solution can be very individually adapted to the specific circumstances and challenges.

Get in touch with us and find out more about the possibilities for development in your company through the use of modular robot cells and camera-guided robots from rbc robotics.