In classic machining lines, raw parts are often still fed manually, which naturally affects the productivity of the production line. Due to various container geometries into which the components from the pre-process are fed, there is often no defined component position and thus no sufficient conditions suitable for automation.

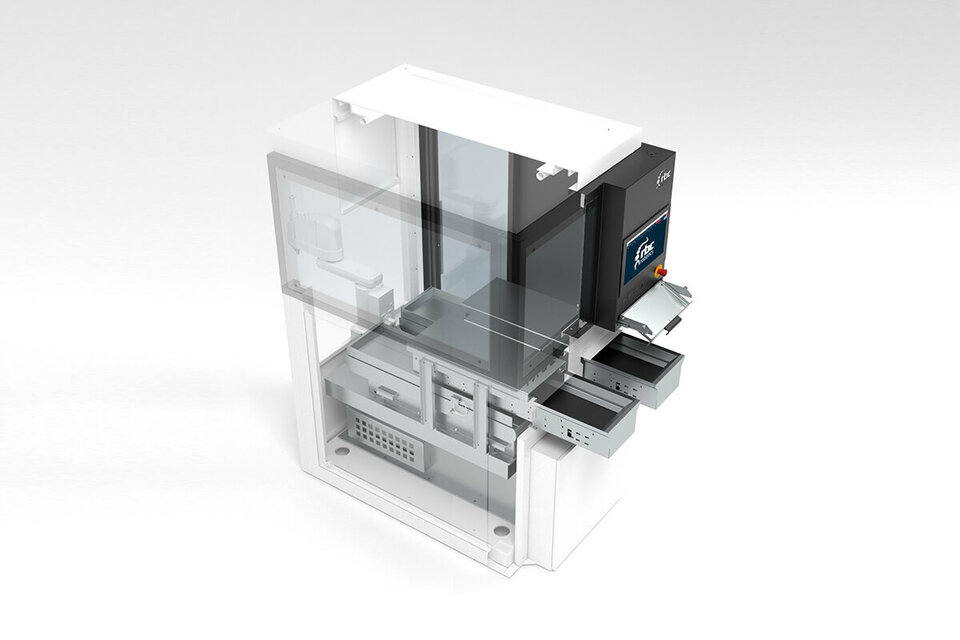

In addition, the use of lifting devices is necessary for high workpiece weights. In order to ensure a continuous supply of raw parts, a high level of personnel is required. rbc Fördertechnik GmbH from Bad Camberg has met these challenges and developed a robot-based system for the feeding of cartesian arranged rotationally symmetrical or cubic, even very heavy workpieces. With this system, pallets or containers can be automatically emptied. Together with a reduced and open line concept, a solution with high customer benefit is created.

The core of the application is a 3D-based detection system that always determines the current position of the components in the container. A high degree of automation reliability is achieved because the removal of unmachined parts is smart. The robot carries out a scene scan before each reach into the crate. The current container situation is the starting position for the next robot access. Component and container require different removal strategies which ensure complete and safe removal. For example, there are often still transport safety devices in the container, which must be removed by the operator in advance. The presence of these transport safety devices is reliably detected and reported by the system. Malfunctions are avoided in this way. The method of removing components from the container is also based on certain criteria. For example, components located at the edge of the crate are picked differently than components located in the middle of the container.

The detection system is stationary or robot-guided, i.e. the sensor which is responsible for detecting the components is guided over the container at a safe distance. When using the preferred sensor, the scan provides extremely stable and reliable data under existing ambient conditions of the production and without the need for additional external light barriers.

Adaptable sensor technology

Depending on the machine's loading situation and other requirements, the detection system can be configured to suit the specific user. For rings weighing around 20 kg, for example, tolerances of up to +/- 2 mm are accepted without compromising automation safety. This value can no longer be sufficiently accurate for smaller and more complex geometries. In this case, work is carried out with modified sensor technology and a smaller scanning distance. Essentially, the laser triangulation or the time-of-flight measurement method is used. In laser triangulation, a laser light line is emitted and picked up again by means of an integrated receiver. The traversed sensor provides 3D point information. The surface condition of the component plays a decisive role in this process. As is well known, high reflection on shiny surfaces then leads to poor detection rates or even to application failure.

Very good results are achieved with the time-of-flight measurement method for object detection and distance measurement. A laser pulse with modulated frequency is used here. This provides the most stable, but somewhat less precise data, which is still sufficiently accurate for many applications.

The corresponding sensor is guided over the object at a distance of approx. 40 mm to approx. 2,500 mm. Depending on the resolution of the sensor system and the distance to the object, accuracies of up to 0.1 mm can be achieved. The sensor signals are recorded and combined with the corresponding movement direction and speed. The result of the object scan is a point cloud. The recording of the point cloud is the preprocessing in the application. The sensor used initially plays the decisive role here. Due to the continuous development of the manufacturers' sensors, significant progress has been made in recent years in terms of performance and size.

The evaluation of the scan data after detection (post-processing) is done by means of a PC-based software. With the system used, the evaluation of the data is component specific. This means that the point cloud is evaluated according to a defined algorithm on lines or circles, which provides very robust and reliable results. The overall geometry of the component does not always play the decisive role in this type of evaluation. For example, it is possible to scan partial features and evaluate only these. The remaining component information is then not relevant, and the application uses only the minimal scan data. This has enormous advantages in terms of data acquisition and evaluation times. The evaluation times are about one second for the usual applications. Another advantage of the system is that several sensors can be evaluated with one PC. For example, the component position in the container can be recorded first, and then partially a geometry area can be recorded for additional inspection of a feature.

In addition, the 3D scanner including evaluation PC is optimally integrated into the overall control concept and offers extensive diagnostic options. A live image of the current scan, switchable languages of the operator dialogues and remote access are mandatory.

The industrial robot with mostly pneumatic gripper is thus able to scan several provided pallets and clear them empty. The components lie roughly pre-oriented on the pallets and on different levels with or without intermediate layers. Especially the reliable detection of a component stack (Z-layer) distinguishes the system.

The changeover to other components is done at the push of a button, if the gripper system can work with the different component geometries. In the case of rings, for example, this can be optimally realised, as this represents a simple component geometry.

After removing the workpiece from the pallet or container, the robot loads the first operation of the processing line and ensures a continuous flow of parts. The influence of the operator at this important interface of the line is thus minimised and is limited to the logistics of container supply and removal.