The proven FX series has received more than a facelift - a thorough revision makes the modular cell fit for the future.

For many years rbc robotics in Bad Camberg has been involved in the modularisation of systems and cells. The focus is on the 6-axis industrial robot with all its technical possibilities. In 2010 the FX series was launched, which is always equipped with an industrial image processing system. The functions concentrate on feeding, separating and buffering of components. The use of modules and good proven standards allows extremely economical automation solutions to be offered.

New challenges, new perspectives

Since 2018 rbc robotics has been a member of the DVS Technology Group. This results in new possibilities, requirements and potentials. Which modules hit the nerve of the customers in 2020 and offer the corresponding added value for the manufacturing companies today and tomorrow?

Within the DVS Group, all specialist companies are ultimately always concerned with the processes of turning, gear cutting and grinding. The essential added value lies in the hard or soft machining of wheels, rings, rollers, shafts, or shaft components. Each processing machine makes different demands on the component feeding or the processing cycle. In addition, there is the problem of different component weights. The aim of all developments within the DVS Group is to combine smart automatic robot loading with an excellent machining process at maximum economic efficiency.

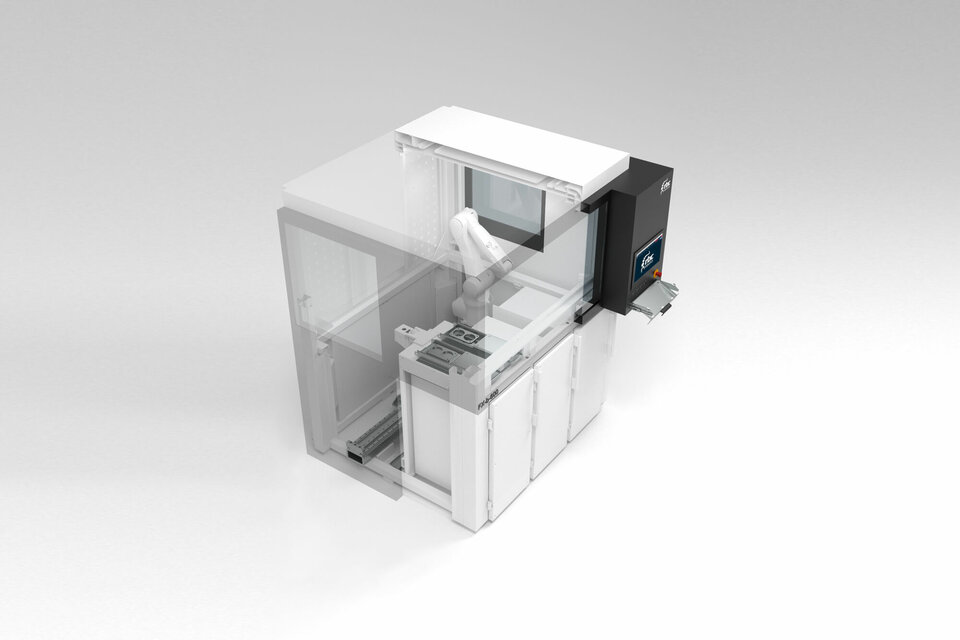

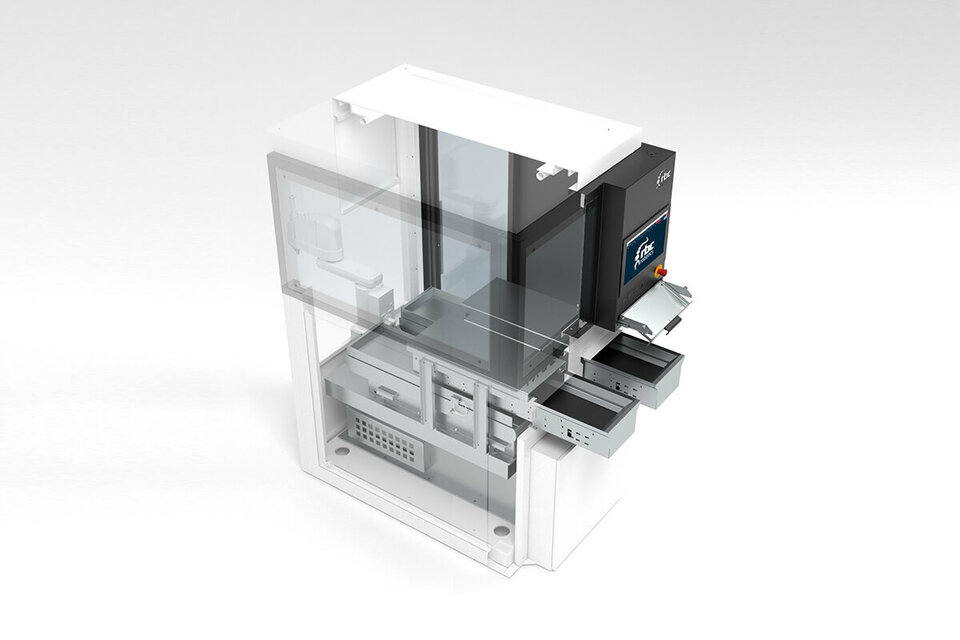

Not only externally changed

Therefore, the FX series has now been redesigned. This is recognizable from the outside by the new, unmistakable design of the sheet metal dress, which presents the machine optimally on its own or in combination with a DVS machine. But of course, it is not only about pure appearance. The inner values have also been fundamentally rethought and optimised.

- The cell now offers advantages in terms of reduced noise emissions and increasing requirements with regard to the absence of particles in components (keyword: clean zone).

- The robot is not visible at first glance and the cell concept is more like a machine than a classic robotic cell. Furthermore, the modules are completely transportable and can therefore be quickly inserted and moved.

- Wall-mounted robots are used, for example, in order to use the installation space of the cell upwards and to keep the footprint of the cell as small as possible. In terms of implementation, this offers the advantage that, in addition to new systems, retrofitting is also less costly.

- In the value stream, the modules can be placed directly at the beginning of the line (Front of Line), within the line or for direct loading of a processing machine, or at the end of the line (End of Line).

Wide range of container formats

Therefore, rbc robotics developed robot modules for the use of full, half and quarter Euro pallets. This covers a wide range of possible container formats. The type designations are FXb 600, FXb 800 and FXb 1200.

The containers and packs that can be used are, for example, pallets with collars and intermediate layers, washing or hardening baskets, small load carriers or stacked trays or blisters.

It does not matter whether raw parts are fed, or finished parts are packed or palletized. The modules are designed so universally that the basic version can be extended accordingly and that in most variants continuous operation of the robot module is possible.

Industrial robots are naturally used in all modules. In the basic variant, manipulators with a payload of 10 kg are used. To increase the agility, rbc robotics installs the robot on an additional linear axis, which was developed within DVS Technology and has outstanding acceleration values with high robustness.

If now a sensor system in the form of a component recognition is added, new dimensions will open up. The "seeing" robot can react to the changing component positions caused, for example, by worn or damaged containers and thus significantly increase process reliability.

The spectrum was extended by rbc robotics in such a way that 3D systems for random binpicking have now been established alongside conventional palletising cells without image processing or integrated 2.5 D image processing systems. These systems enable the picking of rotationally symmetric components in feeding cycles from 8 seconds and emptying rates from 95% of the box content.

Obligatory features are the functionalities for the inward and outward transfer of SPC components, easy loading and unloading of the cells by means of centering and drive-in aids, space-saving sliding doors, central lubrication as well as modular mounting options for cell control on the side or rear wall of the cells.

In general, each cell of the new FX series is equipped with a separate control unit (Siemens S7-F). The operator interface has a 15" monitor with a fold-out keyboard holder and other useful details.

Future viability built in

Additional options, such as laser marking, automatic tool measurement and interlayer handling can be easily integrated into the modules. This always leaves room for expansion, flexibility and adaptation to future production requirements as well as integration into digital or web-based production processes and services.