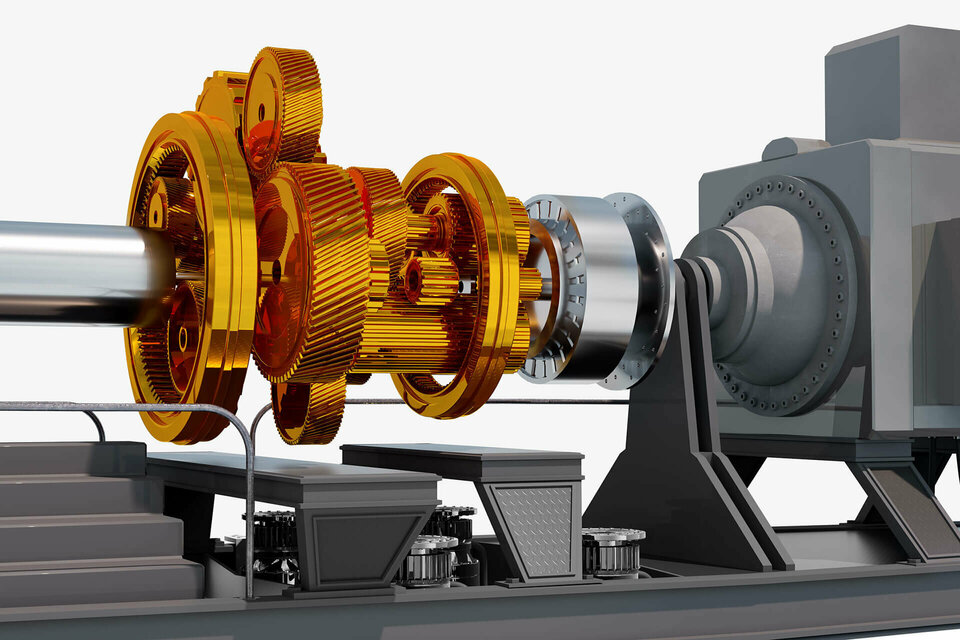

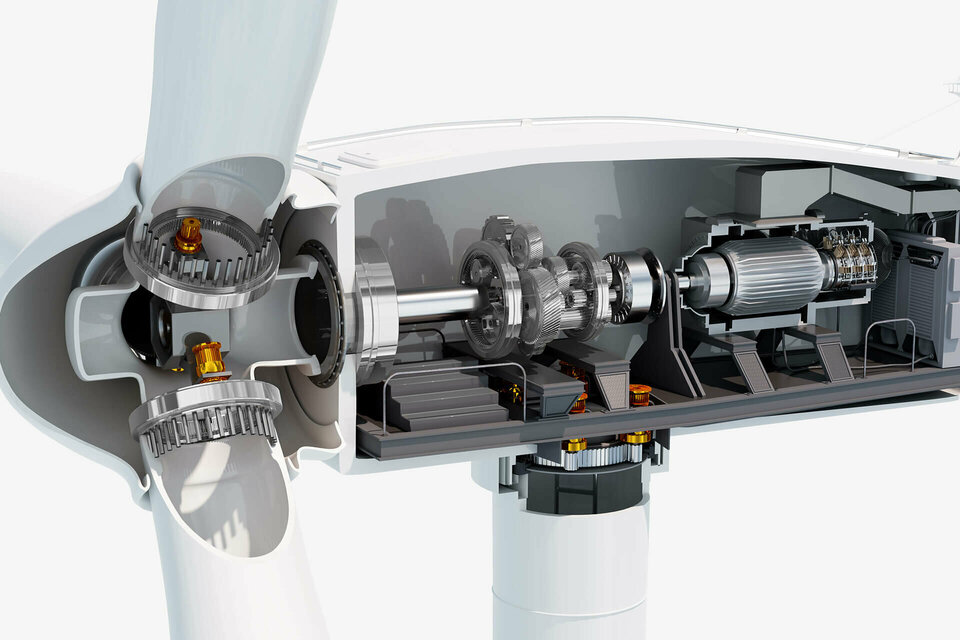

The main drive of a wind turbine is one of the most important assemblies. It transforms the variable speed generated by the rotor to the speed needed by the generator. Larger wind turbines with outputs of several megawatts use high-precision planetary gears, the components of which are manufactured on the machine tools from the Pittler PV series.

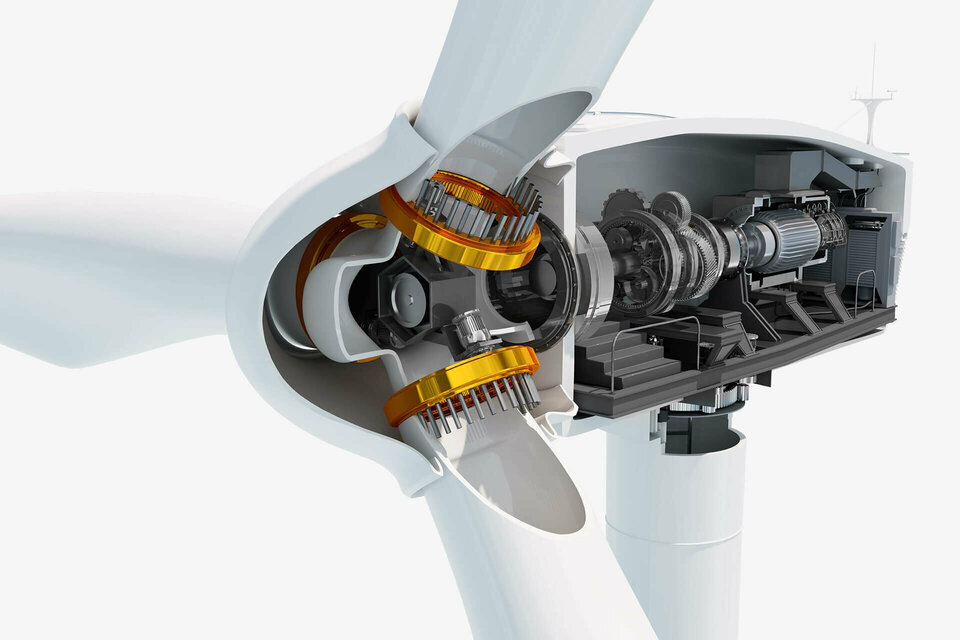

The ability to adjust the pitch and azimuth is critical to the economical operation of a wind turbine, as the ideal wind yield can only be obtained by adjusting the blade (pitch) and wind direction tracking (azimuth). This is also where planetary gears are generally used, for the components of which the DVS TECHNOLOGY GROUP offers tailor-made manufacturing solutions.

Large bearings, such as rotor bearings, blade bearings, and nacelle adjustment bearings, also require maximum accuracy during production – for example, to make them as quiet as possible. And with wind turbines producing ever higher outputs, the dimensions of the bearings required are also getting bigger. This is where we offer economical and at the same highly precise manufacturing solutions, which enable the manufacture of bearing rings with a diameter of up to 4,000 mm.

Especially technologies in the field of modern mobility and drive technology as well as sustainable energy generation have particularly stringent requirements when it comes to manufacturing precision and efficiency. DVS GreenTec supports such trendsetting developments with production quality that continues to redefine the boundaries of what is technically possible.