SKF Lüchow: A milestone in production automation

In an outstanding collaboration, SKF and rbc robotics have set new standards in the automation of production at the SKF plant in Lüchow. The introduction of 29 highly industrialized robot cells, which are in operation around the clock, and an advanced manufacturing concept based on "individuality through modularization", has not only significantly increased production efficiency, but also exceeded the production targets set.

Our customer

SKF in Lüchow is an outstanding example of innovation and efficiency in modern manufacturing technology. As part of the globally active SKF Gruppe, which specializes in the development, production and sale of rolling bearings and seals, the Lüchow site is characterized by its advanced production processes and the implementation of future-oriented technologies. SKF's success in Lüchow is based on a combination of technological expertise, continuous innovation and commitment to quality standards, making this site a role model in the industry and a key player within the SKF Group.

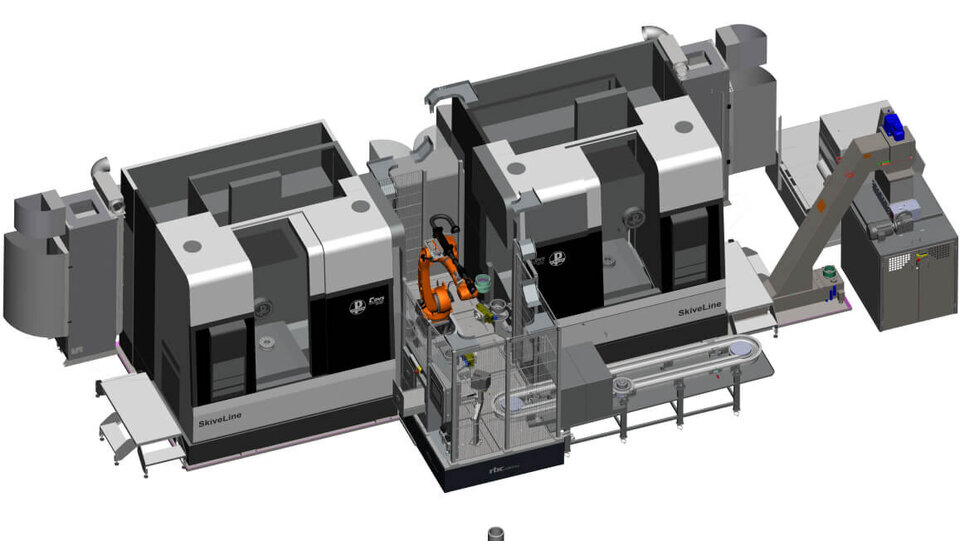

Revolutionary automation in a small space

At the heart of this progress is rbc robotics' cutting-edge automation technology, which enables maximum output to be achieved in a minimum of space. By introducing a modular system concept, two cell types have been developed that allow production lines to be significantly optimized. Each cell of the total of 29 robot cells, equipped with an industrial robot and an integrated seventh linear axis, increases efficiency in 24/7 operation through continuous material feeding and palletizing.

Challenges and innovative solutions

The challenge lay in increasing the degree of autonomy, particularly in the automated feeding and packaging of the finished rings. Despite space restrictions and the need to handle a wide range of ring geometries, the modular solution enabled efficient implementation within the specified time and budget. The rings, which arrive directly from the hardening shop unsorted in containers, are fed by a very dynamic bin-picking robot with pick rates of approx. 10 components per minute. Outstanding results have been achieved in terms of the emptying rate of the containers, the type changeover (up to 40 variants per channel) and the reliability of the overall system. At the end of the production line, the rings are also automatically packed on intermediate layers. This is done with the same basic module of the modularized cell and with even faster pick rates. Teaching the robots is a thing of the past here. The same applies to impact marks and component damage.

Impressive results

The results speak for themselves: a continuous 24/7 supply and packaging of components that avoids downtime, a noticeable reduction in noise levels and a reduction in physical strain for employees. Automation has made it possible for employees to concentrate almost entirely on quality assurance and production processes. In addition, the changeover times of the automation cells are remarkably short, which ensures flexible and efficient production.

A Partnership that Sets Standards

The cooperation between SKF and rbc robotics illustrates the power of effective collaboration in automation technology. By combining technological expertise and common goals, significant advances in production efficiency and technology have been achieved. The project is a clear example of how innovative solutions and strong partnerships can shape the future of the manufacturing industry.

Customized automation: Would you like to discover more case studies for individual automation solutions from rbc robotics? Visit the Smart Flex section of the rbc robotics website.

How satisfied is our customer SKF with this project? Find out in our interview with Helge Koopermann, project manager and process engineer at SKF:

1. how would you describe the current collaboration between SKF and rbc robotics?

Mr. Koopmann: The cooperation is characterized by good communication, joint pursuit of objectives and trusting cooperation.

2. which factors are particularly important to you when selecting a cooperation partner?

Mr. Koopmann: Honest and trusting communication at eye level. Credibility of the implementation of a technical solution.

3. what challenges did you face in your collaboration with rbc robotics and how were they overcome?

Mr. Koopmann: One challenge was the ambitious project schedule. Only 6 months passed between the order being placed in January and the delivery of the first machine in July. rbc robotics also met the promised delivery dates for the subsequent deliveries and the corresponding installations of the robot cells, so that we were able to integrate a new robot cell into production every 2-3 weeks on average. Another challenge was the modular design of the robot cell, which brought many advantages for both rbc robotics and SKF. From SKF's point of view, for example, it was possible to ensure that the cell could be commissioned quickly. I like to recall a best-case scenario in which we managed to have a robot cell delivered by truck on a Friday morning and it was already fully available for production at 10 p.m. the following Sunday at the start of the night shift.

4 How does SKF benefit from the technological expertise of rbc robotics?

Mr. Koopmann: The implementation of the aforementioned project involved the use of bin picking, a new technology on the market, and the associated challenges. The professional approach of rbc robotics in carrying out a benchmarking and the subsequent selection, as well as the transparency regarding the result vis-à-vis SKF, was to our complete satisfaction.

5. how do you see the future development of the cooperation between SKF and rbc robotics? Are there any planned projects to be implemented in the near future?

Mr. Koopmann: From SKF's point of view, nothing stands in the way of future cooperation between SKF and rbc robotics. There has already been talk of further automation with a scope of 5 robot cells in the area of heat treatment.