Focus on EU 7: coated brake discs for fine dust protection

The DVS TECHONOLOGY GROUP is developing manufacturing solutions for the sustainable, high-performance, and cost-efficient machining of coated brake discs.

The DVS TECHONOLOGY GROUP is developing manufacturing solutions for the

The DVS TECHONOLOGY GROUP is developing manufacturing solutions for the sustainable, high-performance, and cost-efficient machining of coated brake discs

A large portion of fine dust emissions in street traffic comes from tire and brake wear. Both sources are the primary focus of the EU 7 emissions standard, which will go into effect in 2025. For the reduction of emissions from the braking system, the coated brake disc is emerging as the preferred technical solution. Compared to conventional brake discs, coated brake discs cause 90% less emissions. In contrast to environmentally harmful brake discs from cast iron, the new coated brake disc is coated with high-strength materials, such as tungsten carbide or titanium carbide, which reduce wear.

Durable, corrosion-resistant, and aesthetic

In addition to this environmentally positive aspect, coated brake discs also offer other benefits: they are durable, corrosion-resistant, and meet the end-users' aesthetic requirements, such as clean rims and shiny surfaces.

But the benefits for motorists and the environment present new challenges for the manufacturers, because the friction surface of every brake disc has to be ground on both sides after coating. Only then can reliable functioning be ensured. In order to meet the high requirements in terms of surface quality, DTV (Disc Thickness Variation), and axial run-out, special processing machines and tools are required in the grinding process, which enable the highest level of precision and cost-efficiency when processing such high-strength coatings.

Solutions from the DVS Technology Group

The DVS TECHONOLOGY GROUP accompanies various OEMs and brake disc manufacturers in the development of these complex and new workpieces. The partners benefit from the Group’s comprehensive know-how and its solutions in the field of grinding machines and abrasives. For example, the DVS subsidiaries Buderus Schleiftechnik and DVS Universal Grinding have ground thousands of coated brake discs in the course of prototype and sample machining over the past few years. In doing so, the experts were able to gain many important and valuable insights on how to yield the best possible grinding process.

Specialist in double-sided grinding

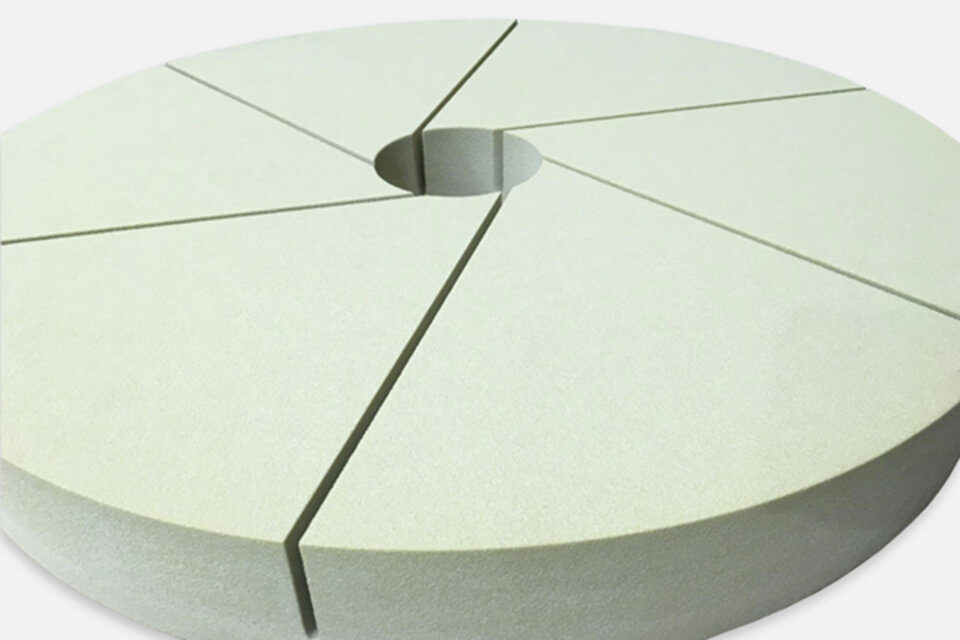

Based on the UGrind, which is already established on the market, DVS Universal Grinding has developed a new machine with two powerful grinding spindles that face each other, specifically for the efficient and precise machining of brake discs: the UGrind DD. This unit allows brake discs to be machined on both sides simultaneously and relies on the so-called double face grinding process. In-process measuring ensures that the workpiece maintains its dimensions. The system determines the position in the Z direction and the thickness of the friction ring before machining. With this information, the brake disc can be ground to dimension on both sides. This ensures compliance with the tight manufacturing tolerances, even if the machining time is short.

Moreover, the necessary throughput is ensured by a robot system for automatic loading and unloading of the machine. The machine can be loaded either from the front or the sides, but a gantry loader can also be set up. The automation can be implemented by the DVS subsidiary rbc robotics in coordination with the Group.

Optimal coordination between machine and abrasive material

The hardness of the coating on the brake disc can reach up to 3,000 HV. To give you a comparison: hardened steels usually have a hardness of about 570 to 900 HV. This means that machining strategies and processes that are common for the machining of conventional materials are not feasible here. So the machining has to be reinvented.

For this purpose, DVS Universal Grinding relies on grinding wheels that were produced within the DVS group of companies. They are the result of a close development cooperation between NAXOS DISKUS and the machine tool experts. The goal was to optimize the grinding process in terms of economy and quality by aiming for a good ratio between material removal and grinding wheel wear. This ensures a high workpiece throughput and low tool costs.

Complete solutions

In addition to grinding machines and abrasives, the DVS TECHONOLOGY GROUP can also rely on project partners who offer the corresponding services and complete solutions with regard to the coating materials, the coating system, as well as the overall integration of complete production systems.

Conclusion

The EU 7 emissions standard will have a major impact on the manufacturing process of brake discs. In order to be able to comply with the specified limit values for the emission of fine dust, innovative manufacturing and process solutions for coated brake discs are required. The DVS TECHONOLOGY GROUP has been involved in these developments for several years and, thanks to the company’s know-how, can offer its partners in the automotive industry comprehensive solutions for grinding processes from a single source.

Progress in automotive development has always pushed the limits of what is technically feasible. Increasingly, however, there are also additional requirements today, such as sustainability, safety and efficiency, as we see in the example of the new Euro7 standard. Would you like to learn more about the synergetic solution of the DVS TECHNOLOGY GROUP on the subject of Euro7-compliant brake discs? Then visit our Website.