For optimum component use: condition monitoring and predictive maintenance

In times of short-term delivery requirements and maximum production capacity utilization, the DVS TECHNOLOGY GROUP relies on the intelligent use of resources - also in the context of tool and component management. Advancing digitalization enables efficient monitoring of machine data and predictive maintenance, the basis for smart tool management and early maintenance measures - an invaluable advantage in times of supply bottlenecks and a shortage of skilled workers.

Maximum machine availability through effective component maintenance

In order to meet increasing customer requirements for shorter delivery times and maximum production capacity utilization, all companies in the DVS TECHNOLOGY GROUP always pursue the goal of minimizing machine downtimes for customers and in their own production and maximizing the availability of machines with effective use of resources.

The tools and components of our CNC machines are an important factor here. As a key factor influencing workpiece quality, we place the highest demands on their precision, performance and reliability.

The tool has direct contact with the workpiece and is responsible for shaping it. Worn, blunt or damaged tools therefore reduce production quality and lead to rejects. It is therefore important for us to plan tool changes, procurement and utilization optimally. A failure of machine components such as motorspindles or multifunctional heads can even lead to a complete breakdown of the machine and therefore the production line. Combined with the high complexity, long delivery times and high costs, this shows the importance of proper maintenance planning and spare parts procurement.

Condition monitoring in the age of Industry 4.0

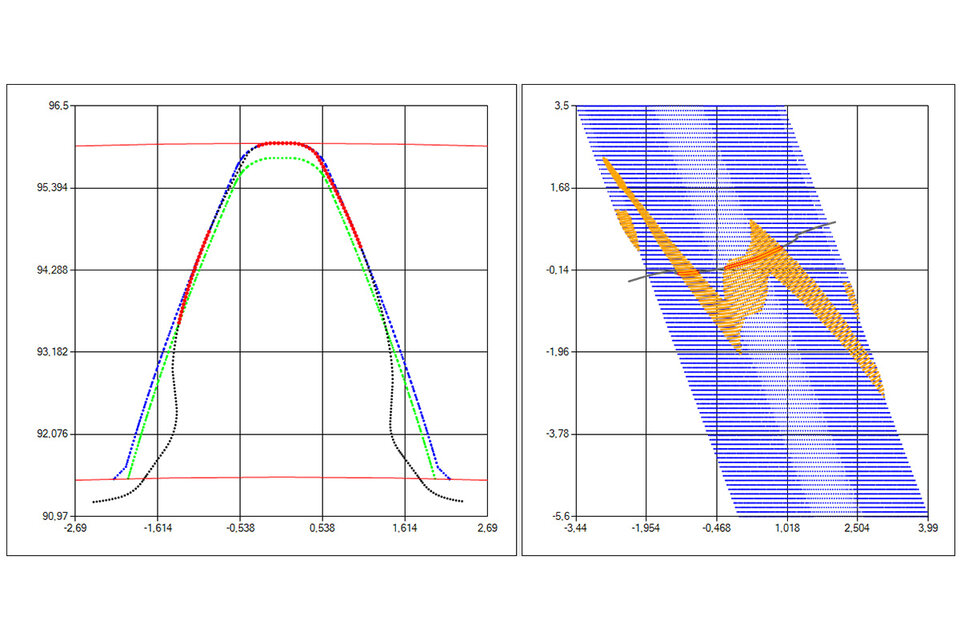

Advancing digitalization enables the decentralized collection and processing of machine data and thus facilitates the condition monitoring of tools and components. For proper condition monitoring and condition-based maintenance, machine components that are particularly critical for availability and functionality must be identified.

Condition monitoring and predictive maintenance of relevant assemblies can also be used to calculate the remaining useful life of tools and components so that maintenance measures can be taken at an early stage. This allows service, spare parts and logistics to be planned with foresight, particularly in times of global supply bottlenecks and a simultaneous shortage of skilled workers.

Condition monitoring and predictive maintenance: the benefits at a glance

- Optimal use of resources: The individual view of the individual components or systems makes it possible to use the remaining wear reserve optimally and adaptively depending on the situation. The aim is to maximize the useful life of the components.

- Higher workpiece quality: Predictive maintenance can reduce the loss of workpiece quality caused by tool wear. In addition, the adaptive control of production cycles up to tool replacement should help to make the best possible use of tool life and service life.

- Efficient planning by predicting the RUL: The prediction of the remaining useful life (RUL) enables the precise forecasting of tool replacement times. As a result, order planning and spare parts procurement can be optimally aligned to this.

- Better maintenance planning: Predictive maintenance can be used to derive the number of workpieces that can still be completed before maintenance/repair is required. This enables demand-oriented planning of maintenance capacities and spare parts procurement, which can reduce unexpected machine downtime.

DVS Edge - The basis for smart machines

DVS Edge forms the basis for smart data evaluations on the machine tools of the DVS TECHNOLOGY GROUP. DVS Edge is used to evaluate the data from machines and components, providing direct insights, such as the Remaining Useful Life of tools.

If desired, the tool information can also be exchanged with DVS Tool Management in order to gain even deeper insights and ensure tool supply.

What do you think?

We are looking forward to your opinion.

Send us an e-mail and let’s talk:

communication@dvs-technology.com