VarioChamfer: Internal Gearing and Deburring in a Single Process

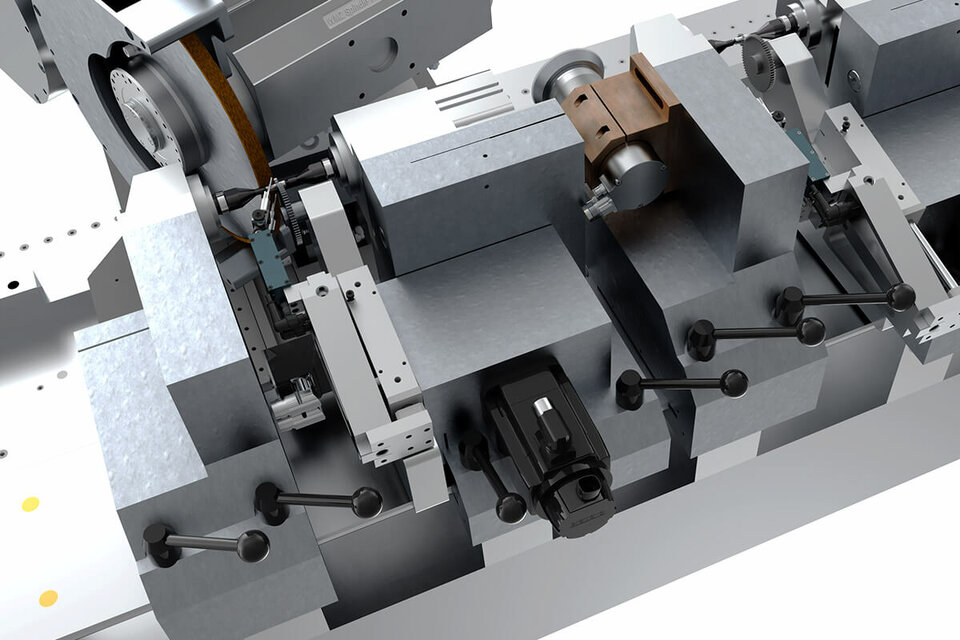

VarioChamfer, the new, patented process from PRÄWEMA enables skiving and deburring in a single clamping when manufacturing gears, thus significantly increasing production efficiency.

At the heart of the VarioChamfer is a rotating tool including a tool spindle. Deburring takes place continuously on the rotating workpiece, whereby the transmission ratio is determined by the specific design and corresponds to the ratio of the number of teeth between the tool and the workpiece.

At first glance, this may appear similar to the conventional production process. Previous solutions used the so-called “Entgratomat” or similar methods, which are primarily intended for the external toothing of gears. For internal gears, which are usually difficult to access due to space restrictions, these methods are limited. Components for high-quality electric drives are especially challenging.

Efficient processing of components for electric drives

PRÄWEMA has been a well-known manufacturer of machine tools for the automotive industry and a market leader in gear honing for many decades. The boom in electromobility and the demand for related components gave the company the impetus to expand the efficient gearing process to include a rational deburring process. The result is VarioChamfer. It was also important that the integration of deburring into the gear cutting machine should have as little impact as possible on the overall machining time of the components.

Gearing and deburring stepped planets and ring gears in a single clamping

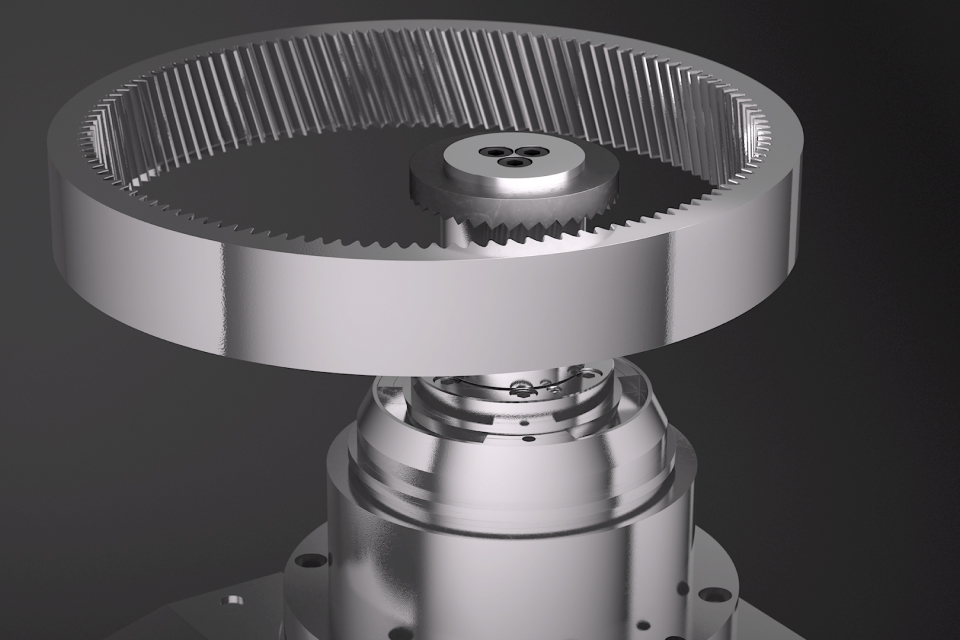

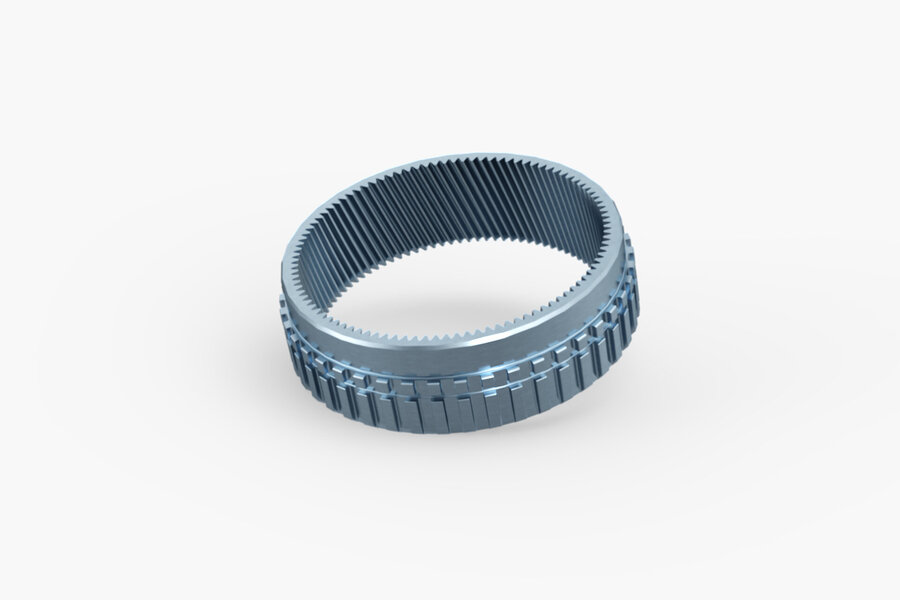

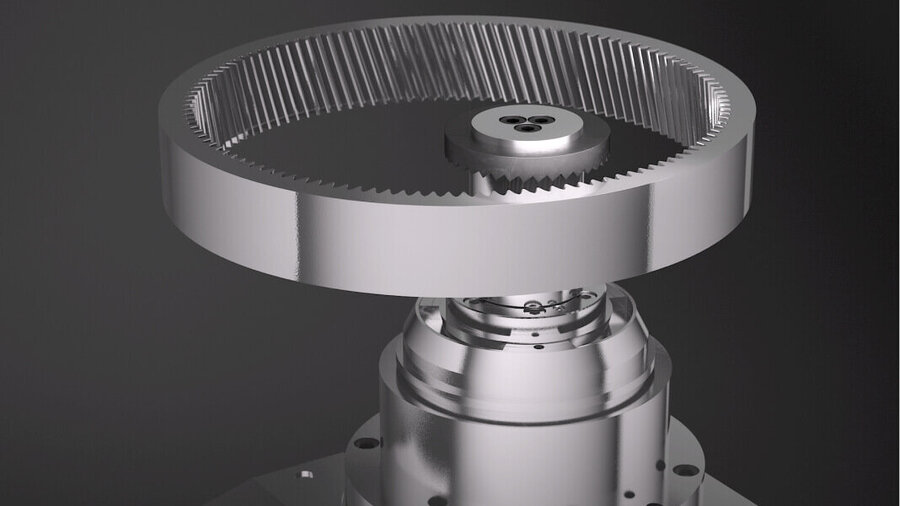

In particular, VarioChamfer is a great solution for the critical components in planetary gears: the so-called stepped planets (see Fig. 1) and the ring gears (see Fig. 2).

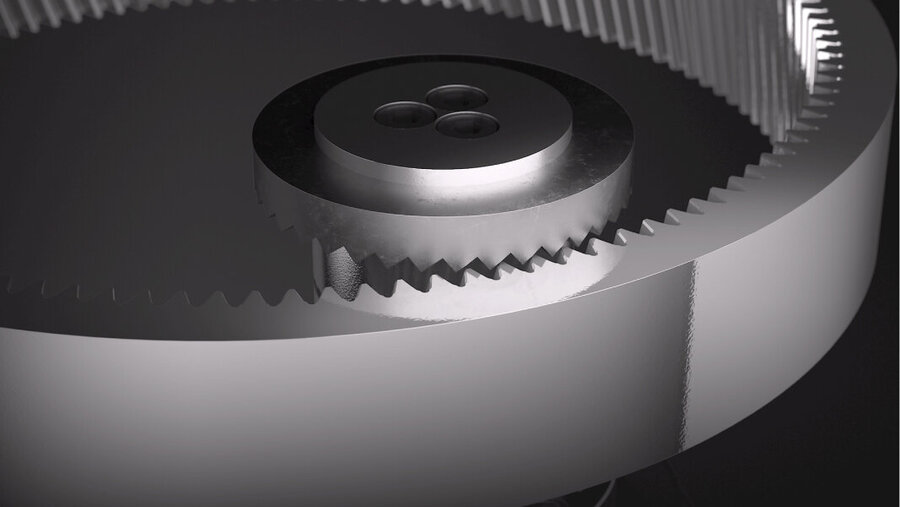

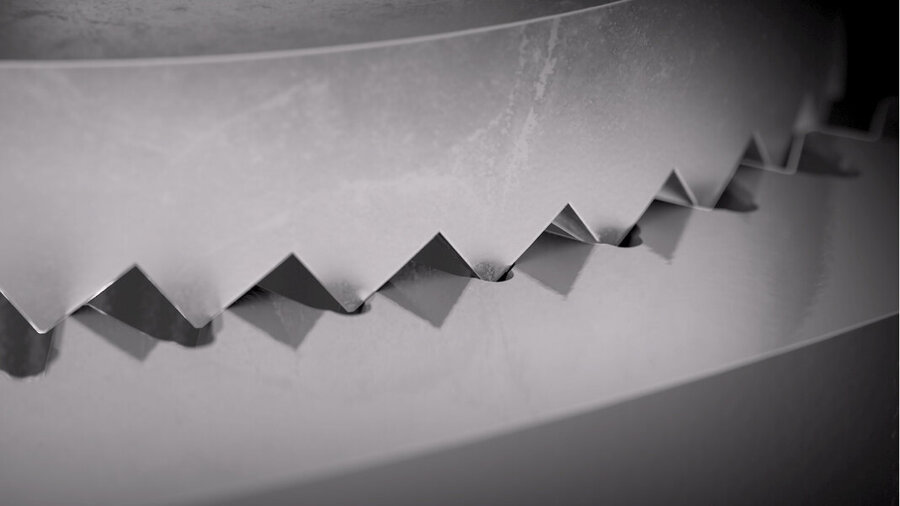

In stepped planets, two gears of different sizes with a small distance from each other comprise the workpiece. Nowadays, the parts are usually machined using skiving, e.g., on the Präwema SynchroFormV. As with any machining operation, this process produces a burr on the exit side of the peeling tool. This burr is inevitably located exactly between the two gears, which are usually arranged at a small distance from each other (see Fig. 3). This is where the VarioChamfer process plays to its full strength due to its space-saving tool.

Ring gears are internally geared components. As in the previous example, the burr occurs on the exit side of the gearing due to the cutting process. Here we have geometric limitations because this area is inside the clamping. Using a similar type of tool as for the stepped planet, collision-free immersion into the workpiece and chamfering is possible.

A particular advantage of the VarioChamfer process is that the workpiece can be deburred in the same clamping in which it was geared (see Fig. 3). It is not necessary to set it down and turn it over, which means no additional solutions are needed. The workpiece is deburred right after gearing.

VarioChamfer helps to save investment costs

VarioChamfer makes it possible to combine processes in the production lines on a small space, which saves investment costs for an additional machine. All processing steps take place inline in one machine. This is particularly important in the series production of transmission components. Thanks to VarioChamfer, for example, a stepped planet can be deburred in less than ten seconds.

Based on principles of kinematics

The concept underlying the VarioChamfer is based on the tried-and-tested backing milling process. This method enables the use of (usually conical) pockets in the tooth flanks. VarioChamfer and backing milling use principles of kinematics, in which the movements of bodies are described purely geometrically with the variables location, time, speed, and acceleration: The circumference of the tool has a cutting edge which gradually plunges into every gap in the workpiece. This is generated by the axes of rotation, which are coupled at a fixed ratio. Breaking it down to a single axis, it can be imagined as follows: When you roll the wheel of a bicycle over the ground, the wheel’s valve points precisely downwards once every revolution. The path of the valve is always the same. Now, if the ground is bent into a circle, after the wheel has rolled through the circle once the valve “immerses” at a different position than when it was rotated the last time. But the ratio between the wheel and diameter can be selected so that the valve always immerses at exactly the same distance, i.e., where the imaginary gap is.

Would you like to learn more about VarioChamfer for gear cutting and deburring in one clamping? Are you looking for other product or technology solutions for gear cutting? The best thing to do is to contact the experts at PRÄWEMA Antriebstechnik directly and without obligation.